Plastic rotational molding, commonly known as rotomolding, is a unique manufacturing process that offers unparalleled flexibility for creating large, ...

READ MOREProduct Series

- - Water Floating Body Series

-

- Rotomolding Development And OEM Processing

- - Rotomolding Fuel Tank

- - Rotomolding Plant Protection Water Tank

- - Rotomolding RV Water Tank

- - Rotomolding Packaging Tool Box

- - Rotomolding Equipment Shell

- - Rotomolding Furniture

- - Rotomolding Toys

- - Rotomolding Cone Bottom Funnel

- - Rotomolding Leak-Proof Tray

- - Rotomolding Traffic Facilities

- - Rotomolding Special-Shaped Air Duct

- - Denitrification Deep Bed Filter T-Type Filter Brick

-

- Sewage Lift

- - Water Treatment Series

- - Aquaculture Barrel Series

-

- Rotational Mold Design And Development

-

- Rotomolding Accessories

Rotomolding Toys Manufacturers

Who are we?

Cixi Junyi Plastic Co., Ltd., since its establishment in 2007, has been located in Cixi, Zhejiang, known as the hometown of rotational molding. The company is strategically located, only 2 kilometers away from Yuyao North High-speed Railway Station, and about 15 kilometers away from the Hangzhou Bay Cross-Sea Bridge. It has convenient transportation and significant geographical advantages.

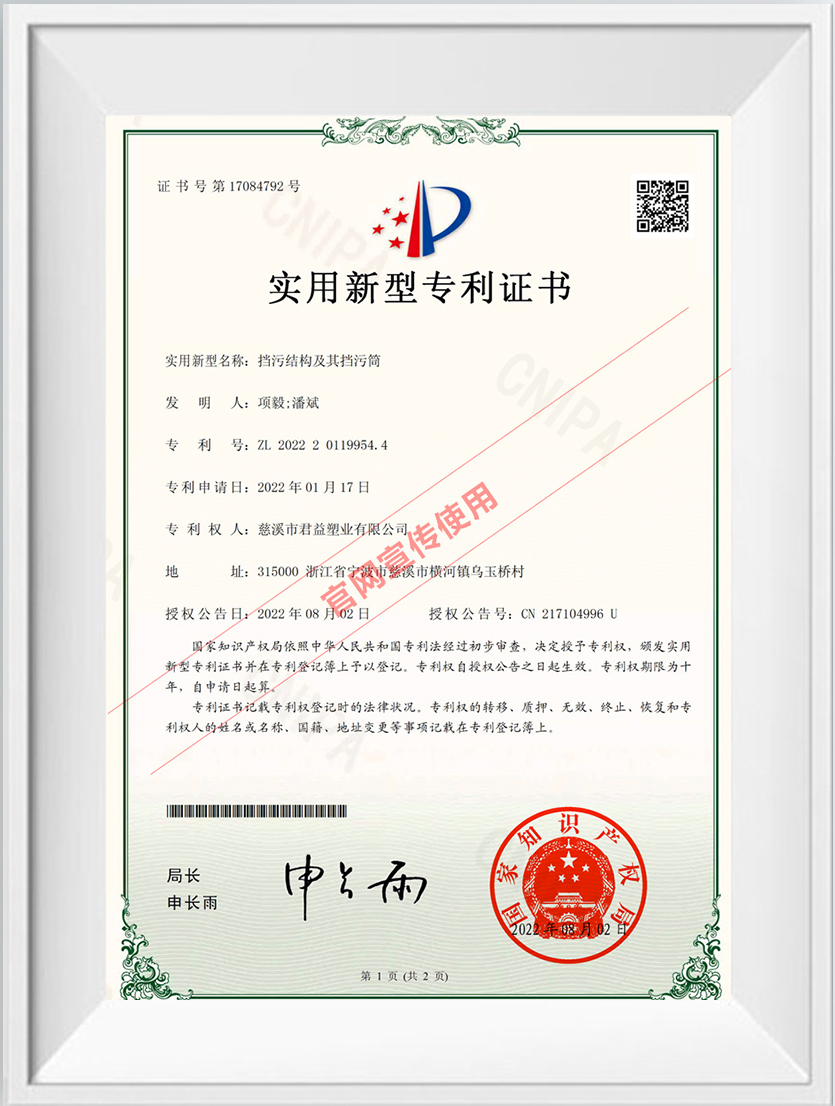

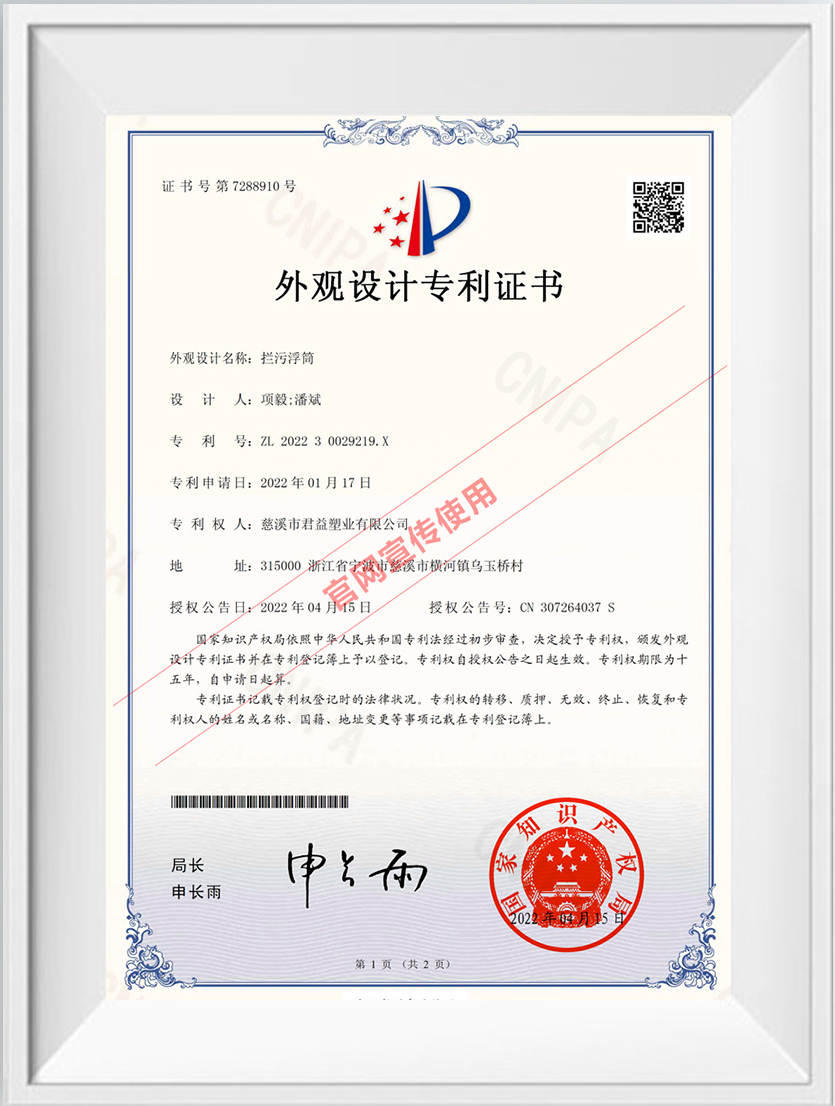

As China Rotomolding Toys Manufacturers and Rotomolding Toys Suppliers, we have won the trust and support of our customers with our stable product quality, R&D strength and after-sales service. The company's main business covers the design and research and development of floating body products. It specializes in the production of marine floats, warning floats, buoys, navigation marks, pipeline dredging floats and other types of marine equipment floating bodies. It also provides OEM and ODM services to meet the individual needs of customers.

The company has advanced production equipment, including dozens of rotating tower rotational molding machines, shuttle rotational molding machines, swing open flame rotational molding machines, and thousands of product molds to ensure the diversification of foaming types and products inside the floating body. of high quality.

Junyi Plastic's service commitment is that our professional team will provide customers with a full range of pre-sales, sales, and after-sales services to ensure that customers can receive high-quality technical support. We value the trust of our customers and always adhere to the service concept of "customer-centric, creating value for customers". In the service process, we continue to accumulate experience, improve service quality, and strengthen service intensity. Through unremitting exploration and continuous improvement, we have established a high-quality and complete after-sales service system. We always start from the actual needs of customers, not only solving customers' worries, but also committed to improving the added value of products.

-

Founded In

0+ -

Production Lines

0+ -

Employee

0+ -

Plant Area

0㎡+

-

-

Floating docks are essential structures for a variety of waterfront applications, offering support for boats, water sports, and leisure activities. Th...

READ MORE -

In the field of industrial design, an equipment shell is more than just the “face” of a product; it is the primary line of defense protecting delicate...

READ MORE -

A 10 Tons PE Mixing Barrel is a critical piece of equipment in the plastic processing industry, primarily used for the blending, homogenizing, and mel...

READ MORE

1. Understanding Rotomolding Technology

Rotomolding technology stands out in the realm of plastic manufacturing due to its unique process and versatile applications. At its core, rotomolding involves the rotational movement of a mold around two perpendicular axes while heated, allowing for the even distribution of melted resin throughout the mold cavity. This method ensures uniform wall thickness and seamless construction, making it ideal for producing a wide range of hollow plastic products, including toys. The precision of rotomolding lies in its ability to control various parameters such as mold temperature, rotation speed, and cooling time. These factors are meticulously managed to achieve consistent wall thickness and structural integrity across different parts of the toy. Cixi Junyi Plastic Co., Ltd. leverage advanced rotational molding machines to precisely regulate these parameters, ensuring high-quality and durable toy production. One of the strengths of rotomolding technology is its compatibility with various types of thermoplastic resins. Depending on the desired properties of the toy—whether it requires flexibility, impact resistance, UV stability, or specific colors—manufacturers can select from a wide range of resin formulations. This flexibility in material choice allows for customization to meet both functional and aesthetic requirements, catering to diverse consumer preferences. Unlike traditional molding methods, rotomolding enables the creation of complex geometries and intricate designs without the need for additional assembly steps. This capability is particularly advantageous in toy manufacturing, where imaginative shapes and vibrant colors are often key selling points. Designers can explore creative possibilities knowing that rotomolding can faithfully replicate their vision in three-dimensional form, enhancing the appeal and play value of the toys. Rotomolded toys are renowned for their durability and safety. The seamless construction and absence of weld lines eliminate potential weak points, ensuring robust performance even under demanding usage conditions. This structural integrity not only enhances the longevity of the toys but also contributes to their safety by reducing the risk of breakage or sharp edges. In an era increasingly focused on sustainability, rotomolding offers inherent eco-friendly benefits. The process generates minimal material waste, as any excess resin can be recycled and reused in subsequent production cycles. This closed-loop approach aligns with global efforts to minimize environmental impact and reduce plastic waste. By choosing rotomolded toys, consumers can support environmentally responsible manufacturing practices without compromising on product quality or safety. Continuous innovation drives advancements in rotomolding technology, expanding its capabilities and applications. Cixi Junyi Plastic Co., Ltd. invest in research and development to enhance mold design, resin formulations, and process efficiency. These innovations pave the way for new product categories and improved manufacturing techniques, ensuring that rotomolding remains a competitive choice in the evolving toy industry landscape. Whether producing classic toys, educational models, or niche collectibles, rotomolding offers the flexibility to meet diverse market demands. Companies like Cixi Junyi Plastic Co., Ltd. stay attuned to market dynamics, leveraging their expertise to introduce innovative toy designs that resonate with modern consumers seeking quality, safety, and value.

2. Advantages of Rotomolding Toys

Rotomolding toys offer a multitude of advantages that make them a preferred choice in the toy manufacturing industry. From durability to design flexibility, each aspect contributes to their appeal among consumers alike.

a)Durability and Strength: One of the primary advantages of rotomolding toys is their exceptional durability. The seamless construction eliminates weak points such as weld lines, common in other molding processes, ensuring toys can withstand rough handling and outdoor environments. This durability not only enhances the longevity of the toys but also reduces the need for repairs or replacements, making them a cost-effective choice for both consumers and retailers.

b)Design Flexibility and Complexity: Rotomolding technology allows for unparalleled design flexibility in toy manufacturing. Designers can create complex shapes, intricate details, and unique textures that would be challenging or impossible to achieve with conventional molding methods. The process accommodates large, hollow structures without the constraints of mold complexity, offering endless possibilities for imaginative and innovative toy designs. Whether producing whimsical characters, realistic replicas, or educational models, rotomolding enables manufacturers to cater to diverse consumer preferences and market trends effectively.

c)Safety and Consumer Confidence: Safety is paramount in toy manufacturing, and rotomolding toys excel in meeting stringent safety standards. The seamless, stress-free construction reduces the risk of sharp edges or breakage, enhancing the safety profile of the toys, especially important for children's play items. Cixi Junyi Plastic Co., Ltd. conduct rigorous testing and quality assurance procedures to ensure compliance with international safety regulations, providing consumers with confidence in the products' reliability and suitability for children of all ages.

d)Color and Texture Options: Rotomolding offers extensive possibilities for incorporating vibrant colors and various textures into toy designs. Pigments can be evenly distributed throughout the resin, resulting in uniform and long-lasting coloration that resists fading over time, even with prolonged exposure to sunlight. Textures ranging from smooth surfaces to tactile finishes can be achieved, enhancing sensory engagement and aesthetic appeal. These customizable options allow manufacturers to create visually appealing toys that attract attention on store shelves and captivate young imaginations.

e)Versatility Across Toy Categories: The versatility of rotomolding extends across a wide range of toy categories, from ride-on toys and playground equipment to educational models and novelty items. Cixi Junyi Plastic Co., Ltd. cater to diverse market segments by leveraging the process's adaptability to different shapes, sizes, and functionalities. This versatility enables toy brands to innovate continually, introducing new designs and product lines that resonate with evolving consumer preferences and play trends.

English

English عربى

عربى