Plastic rotational molding, commonly known as rotomolding, is a unique manufacturing process that offers unparalleled flexibility for creating large, ...

READ MOREProduct Series

- - Water Floating Body Series

-

- Rotomolding Development And OEM Processing

- - Rotomolding Fuel Tank

- - Rotomolding Plant Protection Water Tank

- - Rotomolding RV Water Tank

- - Rotomolding Packaging Tool Box

- - Rotomolding Equipment Shell

- - Rotomolding Furniture

- - Rotomolding Toys

- - Rotomolding Cone Bottom Funnel

- - Rotomolding Leak-Proof Tray

- - Rotomolding Traffic Facilities

- - Rotomolding Special-Shaped Air Duct

- - Denitrification Deep Bed Filter T-Type Filter Brick

-

- Sewage Lift

- - Water Treatment Series

- - Aquaculture Barrel Series

-

- Rotational Mold Design And Development

-

- Rotomolding Accessories

Rotomolding Packaging Tool Box Manufacturers

Who are we?

Cixi Junyi Plastic Co., Ltd., since its establishment in 2007, has been located in Cixi, Zhejiang, known as the hometown of rotational molding. The company is strategically located, only 2 kilometers away from Yuyao North High-speed Railway Station, and about 15 kilometers away from the Hangzhou Bay Cross-Sea Bridge. It has convenient transportation and significant geographical advantages.

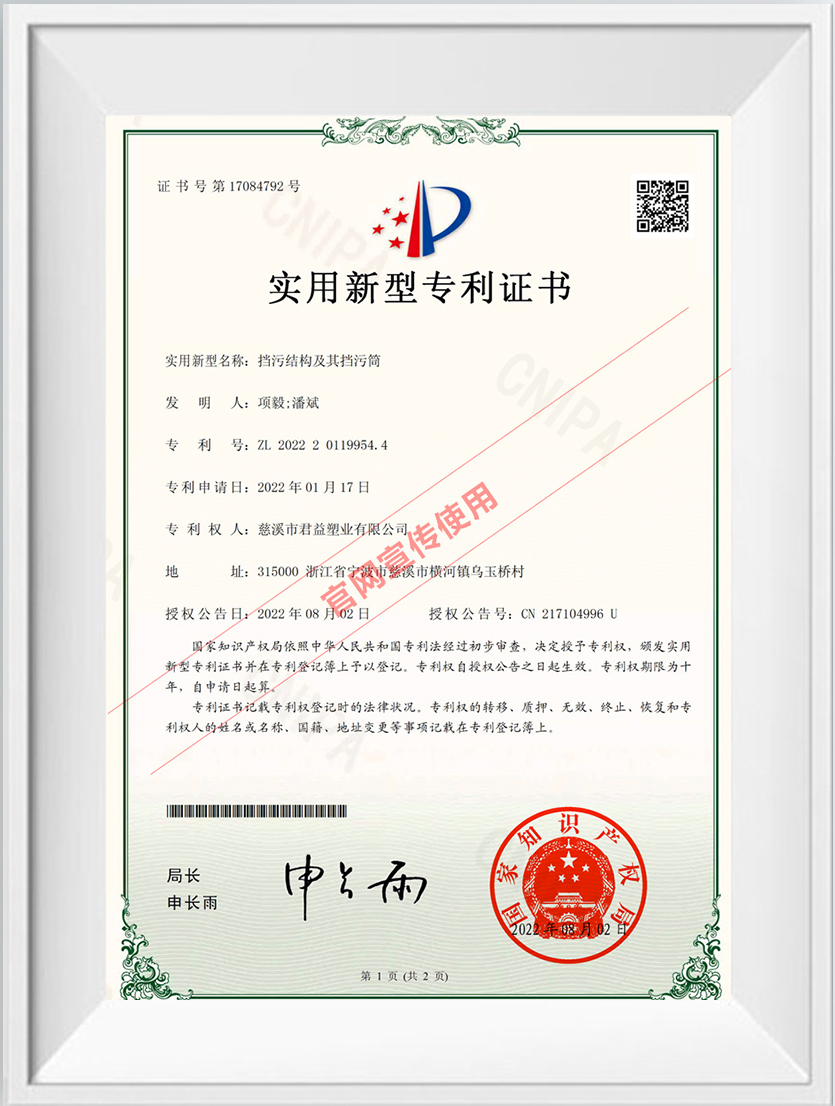

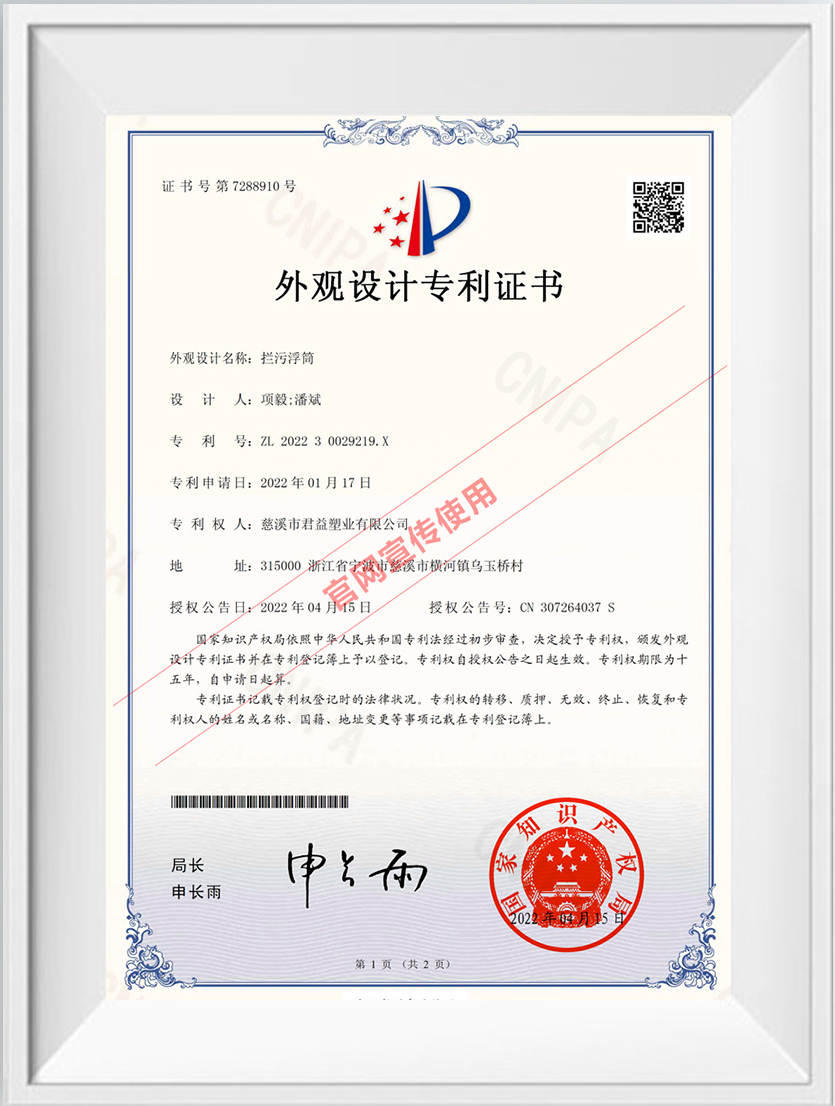

As China Rotomolding Packaging Tool Box Manufacturers and Rotomolding Packaging Tool Box Suppliers, we have won the trust and support of our customers with our stable product quality, R&D strength and after-sales service. The company's main business covers the design and research and development of floating body products. It specializes in the production of marine floats, warning floats, buoys, navigation marks, pipeline dredging floats and other types of marine equipment floating bodies. It also provides OEM and ODM services to meet the individual needs of customers.

The company has advanced production equipment, including dozens of rotating tower rotational molding machines, shuttle rotational molding machines, swing open flame rotational molding machines, and thousands of product molds to ensure the diversification of foaming types and products inside the floating body. of high quality.

Junyi Plastic's service commitment is that our professional team will provide customers with a full range of pre-sales, sales, and after-sales services to ensure that customers can receive high-quality technical support. We value the trust of our customers and always adhere to the service concept of "customer-centric, creating value for customers". In the service process, we continue to accumulate experience, improve service quality, and strengthen service intensity. Through unremitting exploration and continuous improvement, we have established a high-quality and complete after-sales service system. We always start from the actual needs of customers, not only solving customers' worries, but also committed to improving the added value of products.

-

Founded In

0+ -

Production Lines

0+ -

Employee

0+ -

Plant Area

0㎡+

-

-

Floating docks are essential structures for a variety of waterfront applications, offering support for boats, water sports, and leisure activities. Th...

READ MORE -

In the field of industrial design, an equipment shell is more than just the “face” of a product; it is the primary line of defense protecting delicate...

READ MORE -

A 10 Tons PE Mixing Barrel is a critical piece of equipment in the plastic processing industry, primarily used for the blending, homogenizing, and mel...

READ MORE

1.What are the Advantages of Rotomolding Packaging Tool Box?

Rotomolding has become increasingly favored as the manufacturing method for packaging tool boxes, particularly due to its unique advantages in producing durable and versatile products. Unlike traditional molding techniques such as injection molding or blow molding, rotomolding involves the use of powdered plastic resin that is evenly distributed and melted within a heated mold. The mold is then rotated along multiple axes, ensuring that the molten resin coats the entire interior surface uniformly. This rotational process results in seamless, stress-free products that exhibit excellent durability, making them ideal for applications where reliability and resilience are paramount.

The durability of rotomolded packaging tool boxes stems from their seamless construction, which eliminates the weak points and potential failure areas typically associated with joints or seams in other manufacturing processes. This seamless design not only enhances the structural integrity of the tool boxes but also improves their resistance to impact, corrosion, and harsh environmental conditions. As a result, rotomolded tool boxes are well-suited for use in diverse industries such as construction, automotive, agriculture, and logistics, where ruggedness and long-term performance are essential requirements.

Rotomolding allows for the production of tool boxes with complex shapes and configurations without the need for additional assembly or fabrication steps. This capability enables manufacturers to create customized solutions tailored to specific applications and user preferences. From ergonomic designs with integrated handles and secure locking mechanisms to specialized compartments for organizing tools and accessories, rotomolded tool boxes offer versatility that meets the evolving demands of modern workplaces.

2.How Does Rotomolding Ensure Durability and Longevity in Tool Box Design?

Rotomolding's ability to ensure durability and longevity in tool box design is rooted in its manufacturing process and the properties of the materials used. During rotomolding, the powdered plastic resin, typically LLDPE (Linear Low-Density Polyethylene), is heated and rotated within the mold until it evenly coats the mold's interior surfaces. This rotational movement distributes the resin uniformly, resulting in tool boxes with consistent wall thickness and structural integrity throughout.

The seamless construction of rotomolded tool boxes eliminates potential weak points such as seams or joints, which are vulnerable to stress and wear over time. This seamless design not only enhances the tool box's resistance to impact and deformation but also improves its ability to withstand exposure to UV radiation, chemicals, and extreme temperatures. As a result, rotomolded tool boxes maintain their functionality and aesthetic appeal over prolonged periods of use, making them a cost-effective investment for industries requiring reliable storage solutions.

The durability of rotomolded tool boxes translates into reduced maintenance and replacement costs, as they are less prone to damage and deterioration compared to tool boxes made using conventional manufacturing methods. This durability factor is particularly advantageous in industries where equipment longevity and operational efficiency are critical considerations.

3.What Customization Options Are Available for Rotomolding Packaging Tool Box?

Customization options for rotomolded packaging tool boxes are extensive, offering manufacturers and end-users flexibility in design, functionality, and branding. Rotomolding allows for the creation of tool boxes in various sizes and shapes, ranging from compact handheld cases to large, multi-compartment storage units. This versatility enables tool boxes to be tailored to specific applications, whether for housing hand tools, power tools, diagnostic equipment, or specialized instruments.

In terms of design features, rotomolded tool boxes can incorporate ergonomic handles, robust hinges, secure latches, and integrated locking mechanisms to enhance usability and security. The interiors of the tool boxes can be customized with dividers, trays, and foam inserts to organize and protect tools during transportation and storage. Custom color options and the ability to add logos or labels further personalize the tool boxes, aligning them with corporate branding or user preferences.

Rotomolded tool boxes can be designed to meet specific industry standards and regulatory requirements, ensuring compliance with safety and operational guidelines. Whether used in construction sites, manufacturing facilities, service vehicles, or outdoor environments, customized rotomolded tool boxes offer reliability and functionality that optimize workflow efficiency and enhance productivity.

At Cixi Junyi Plastic Co., Ltd., we leverage our expertise in rotomolding and blow molding processes to manufacture high-quality packaging tool boxes that meet the diverse needs of our customers. With a dedicated international trade department and comprehensive in-house services—from initial product design and mold development to final manufacturing and distribution—we ensure that every tool box delivers exceptional performance and durability. Our commitment to quality assurance and customer satisfaction guarantees that inquiries are handled promptly and solutions are tailored to meet the unique requirements of each client, reinforcing our reputation as a trusted supplier in the industry.

English

English عربى

عربى