Plastic rotational molding, commonly known as rotomolding, is a unique manufacturing process that offers unparalleled flexibility for creating large, ...

READ MOREProduct Series

- - Water Floating Body Series

-

- Rotomolding Development And OEM Processing

- - Rotomolding Fuel Tank

- - Rotomolding Plant Protection Water Tank

- - Rotomolding RV Water Tank

- - Rotomolding Packaging Tool Box

- - Rotomolding Equipment Shell

- - Rotomolding Furniture

- - Rotomolding Toys

- - Rotomolding Cone Bottom Funnel

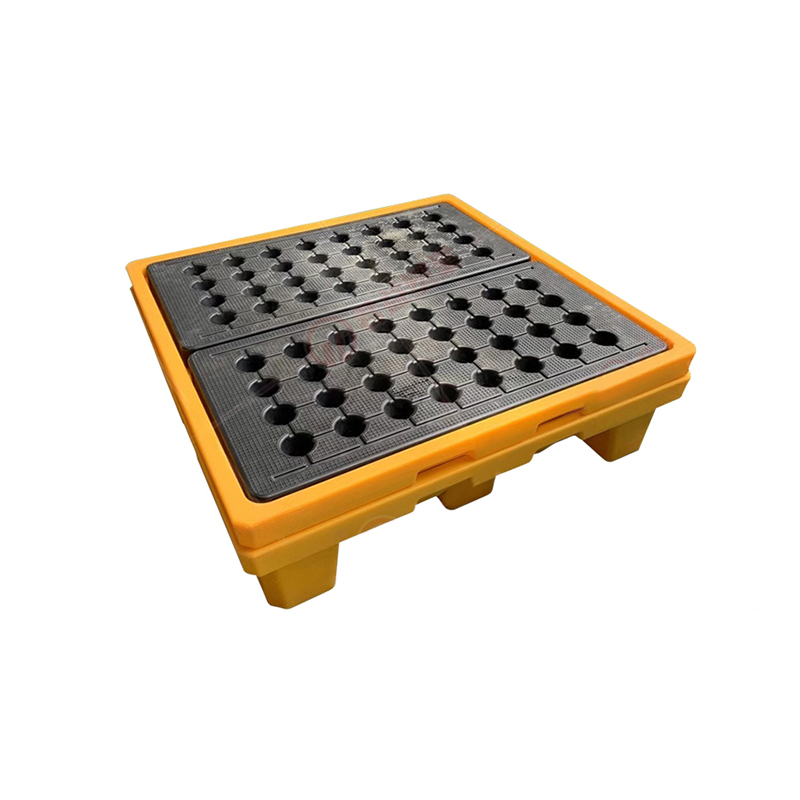

- - Rotomolding Leak-Proof Tray

- - Rotomolding Traffic Facilities

- - Rotomolding Special-Shaped Air Duct

- - Denitrification Deep Bed Filter T-Type Filter Brick

-

- Sewage Lift

- - Water Treatment Series

- - Aquaculture Barrel Series

-

- Rotational Mold Design And Development

-

- Rotomolding Accessories

Who are we?

Cixi Junyi Plastic Co., Ltd., since its establishment in 2007, has been located in Cixi, Zhejiang, known as the hometown of rotational molding. The company is strategically located, only 2 kilometers away from Yuyao North High-speed Railway Station, and about 15 kilometers away from the Hangzhou Bay Cross-Sea Bridge. It has convenient transportation and significant geographical advantages.

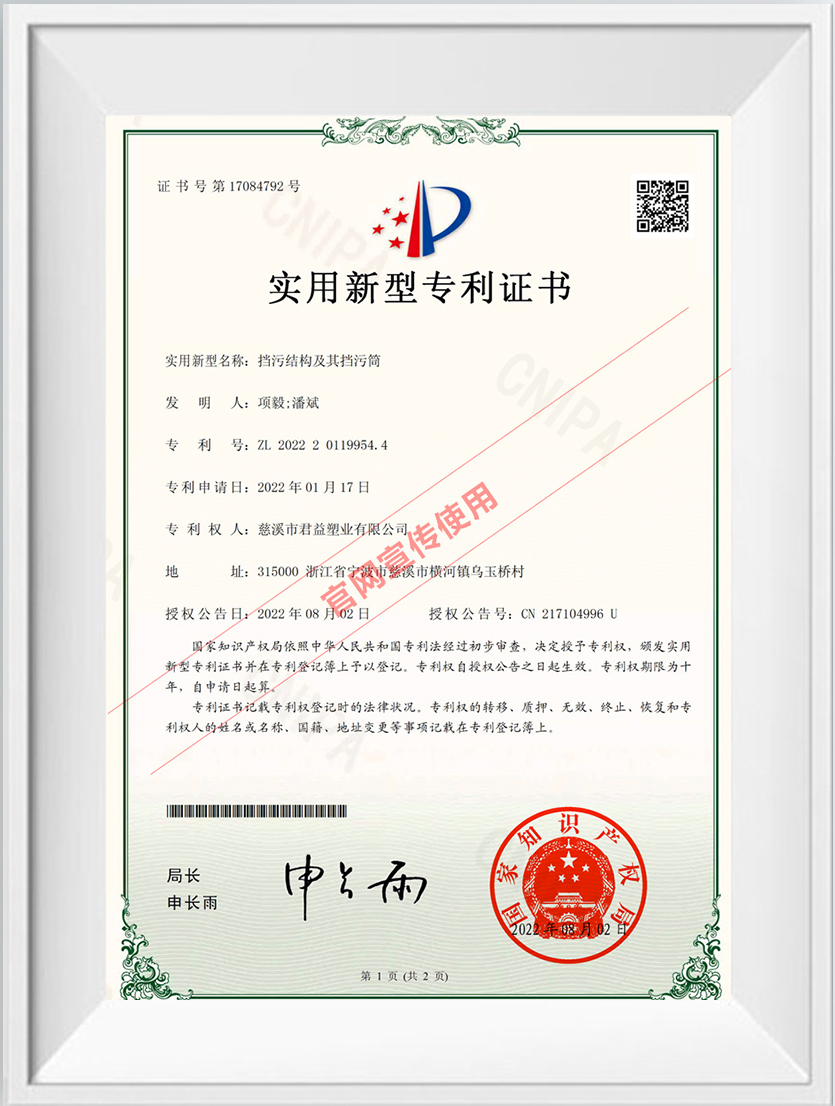

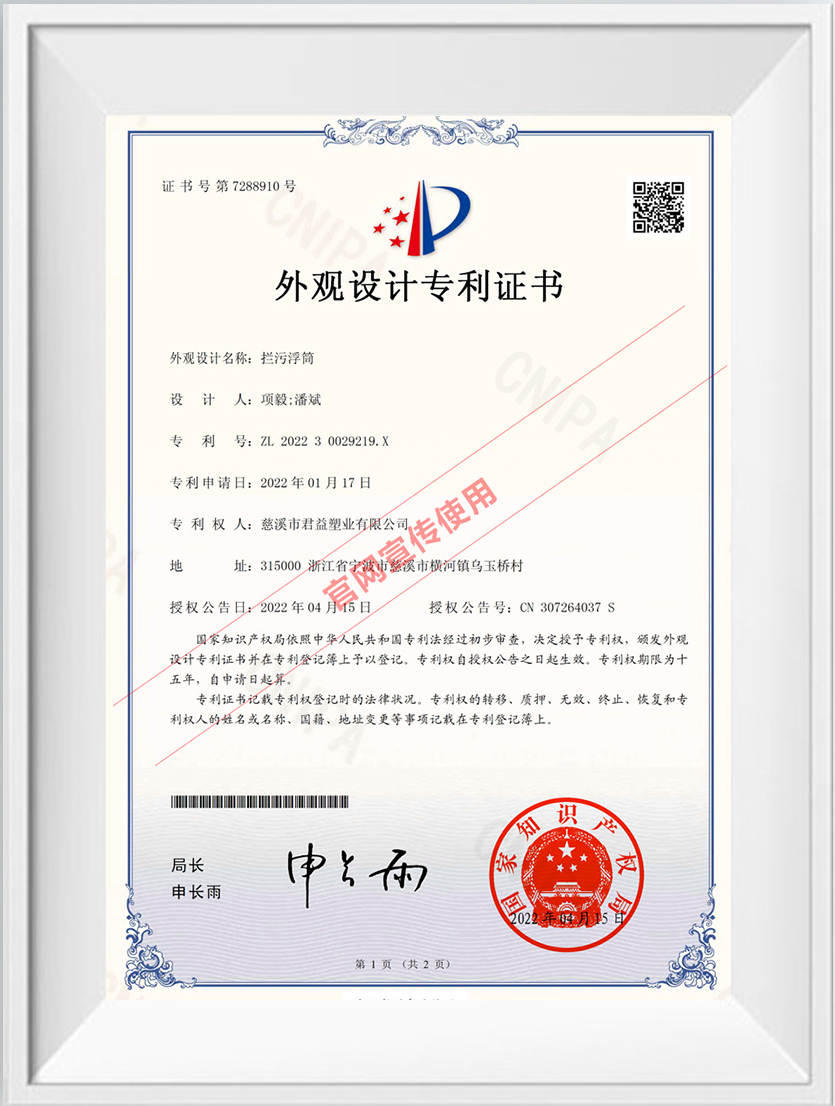

As China Rotomolding Leak-Proof Tray Manufacturers and Rotomolding Leak-Proof Tray Suppliers, we have won the trust and support of our customers with our stable product quality, R&D strength and after-sales service. The company's main business covers the design and research and development of floating body products. It specializes in the production of marine floats, warning floats, buoys, navigation marks, pipeline dredging floats and other types of marine equipment floating bodies. It also provides OEM and ODM services to meet the individual needs of customers.

The company has advanced production equipment, including dozens of rotating tower rotational molding machines, shuttle rotational molding machines, swing open flame rotational molding machines, and thousands of product molds to ensure the diversification of foaming types and products inside the floating body. of high quality.

Junyi Plastic's service commitment is that our professional team will provide customers with a full range of pre-sales, sales, and after-sales services to ensure that customers can receive high-quality technical support. We value the trust of our customers and always adhere to the service concept of "customer-centric, creating value for customers". In the service process, we continue to accumulate experience, improve service quality, and strengthen service intensity. Through unremitting exploration and continuous improvement, we have established a high-quality and complete after-sales service system. We always start from the actual needs of customers, not only solving customers' worries, but also committed to improving the added value of products.

-

Founded In

0+ -

Production Lines

0+ -

Employee

0+ -

Plant Area

0㎡+

-

-

Floating docks are essential structures for a variety of waterfront applications, offering support for boats, water sports, and leisure activities. Th...

READ MORE -

In the field of industrial design, an equipment shell is more than just the “face” of a product; it is the primary line of defense protecting delicate...

READ MORE -

A 10 Tons PE Mixing Barrel is a critical piece of equipment in the plastic processing industry, primarily used for the blending, homogenizing, and mel...

READ MORE

1. Manufacturing Process of Rotomolded Leak-proof Trays

The manufacturing of rotomolded leak-proof trays at Cixi Junyi Plastic Co., Ltd., follows a precise and controlled process to ensure the highest standards of quality and reliability. Mold Design and Preparation: The process begins with meticulous mold design using advanced CAD (Computer-Aided Design) software. Engineers at Cixi Junyi Plastic Co., Ltd., create molds that reflect the exact specifications of the tray design. These molds are typically made from aluminum or steel to withstand repeated use and maintain dimensional accuracy. Material Selection: The choice of material is critical to the performance and longevity of rotomolded trays. High-density polyethylene (HDPE) and polypropylene (PP) are preferred due to their excellent chemical resistance, durability, and UV stability. These materials ensure that the trays can withstand exposure to a wide range of substances without degradation. Powder Loading: The manufacturing process commences with the loading of powdered resin into the mold cavity. The resin powder is carefully measured to achieve the desired wall thickness and structural integrity of the tray. This step is crucial as it lays the foundation for uniform distribution of material during the subsequent heating and rotation stages. Heating Stage: Once loaded, the mold enters a high-temperature oven where it rotates bi-axially along two perpendicular axes. This rotational motion ensures that the resin powder evenly coats the inner surfaces of the mold as it melts. The precise control of temperature and rotational speed is essential to achieve uniform wall thickness and eliminate any potential weak points in the tray structure. Cooling and Solidification: After the resin has completely melted and coated the mold surfaces, the mold is gradually cooled. This controlled cooling phase solidifies the melted resin into a durable and leak-proof tray. Cooling is typically achieved by circulating air or water around the mold, ensuring that the tray retains its shape and dimensional accuracy. Demolding and Finishing: Once cooled, the mold undergoes demolding, where the newly formed tray is carefully removed from the mold cavity. Any excess material or flash is trimmed and smoothed to achieve a clean and professional finish. Quality control inspectors at Cixi Junyi Plastic Co., Ltd., meticulously examine each tray for dimensional accuracy, surface finish, and leak resistance before approving it for packaging and shipment. Testing and Quality Assurance: Every rotomolded tray produced undergoes rigorous testing to ensure it meets stringent quality standards. This includes pressure testing to verify leak resistance, dimensional checks to confirm accuracy, and visual inspections for any defects. By adhering to comprehensive quality assurance protocols, Cixi Junyi Plastic Co., Ltd., guarantees that each tray performs reliably in its intended application. Continuous Improvement: As part of their commitment to excellence, Cixi Junyi Plastic Co., Ltd., continuously seeks to enhance their manufacturing processes. They invest in research and development to explore new materials, refine production techniques, and adopt technological advancements that improve efficiency and sustainability.

2. Applications in Diverse Industries

Rotomolded leak-proof trays manufactured by Cixi Junyi Plastic Co., Ltd., serve critical roles across a wide spectrum of industries due to their durability, chemical resistance, and customizable design capabilities.

a)Pharmaceutical Industry: In pharmaceutical manufacturing and distribution, maintaining a sterile and organized environment is paramount. Rotomolded trays are used to safely store and transport medical supplies, vials, and sensitive equipment. Their leak-proof nature ensures that spills and contamination risks are minimized, meeting stringent hygiene standards.

b)Food Processing and Agriculture: Food processing facilities rely on rotomolded trays for handling and transporting perishable goods, such as fruits, vegetables, and meats. These trays are resistant to acids, alkalis, and cleaning chemicals, making them suitable for use in harsh agricultural environments, including nurseries and greenhouses.

c)Chemical Storage and Hazardous Materials Handling: In chemical manufacturing and storage facilities, where corrosive substances are handled, leak-proof trays play a crucial role in preventing spills and containing hazardous materials. These trays are designed to withstand exposure to acids, bases, solvents, and oils, ensuring safety and compliance with environmental regulations.

d)Automotive and Engineering: Automotive workshops and engineering firms utilize rotomolded trays to organize tools, parts, and components. These trays can withstand heavy loads and repetitive use, making them ideal for storing automotive fluids, greases, and small mechanical parts. Their robust construction ensures longevity in demanding workshop environments.

e)Customized Industrial Applications: Beyond standard uses, Cixi Junyi Plastic Co., Ltd., offers customization options for rotomolded trays to meet specific industrial requirements. This includes modifying tray dimensions, integrating dividers, adding handles, or incorporating specialized fittings. Such tailored solutions ensure that trays seamlessly integrate into diverse industrial workflows, optimizing efficiency and organization.

English

English عربى

عربى