Plastic rotational molding, commonly known as rotomolding, is a unique manufacturing process that offers unparalleled flexibility for creating large, ...

READ MOREProduct Series

- - Water Floating Body Series

-

- Rotomolding Development And OEM Processing

- - Rotomolding Fuel Tank

- - Rotomolding Plant Protection Water Tank

- - Rotomolding RV Water Tank

- - Rotomolding Packaging Tool Box

- - Rotomolding Equipment Shell

- - Rotomolding Furniture

- - Rotomolding Toys

- - Rotomolding Cone Bottom Funnel

- - Rotomolding Leak-Proof Tray

- - Rotomolding Traffic Facilities

- - Rotomolding Special-Shaped Air Duct

- - Denitrification Deep Bed Filter T-Type Filter Brick

-

- Sewage Lift

- - Water Treatment Series

- - Aquaculture Barrel Series

-

- Rotational Mold Design And Development

-

- Rotomolding Accessories

Rotomolding Equipment Shell Manufacturers

Who are we?

Cixi Junyi Plastic Co., Ltd., since its establishment in 2007, has been located in Cixi, Zhejiang, known as the hometown of rotational molding. The company is strategically located, only 2 kilometers away from Yuyao North High-speed Railway Station, and about 15 kilometers away from the Hangzhou Bay Cross-Sea Bridge. It has convenient transportation and significant geographical advantages.

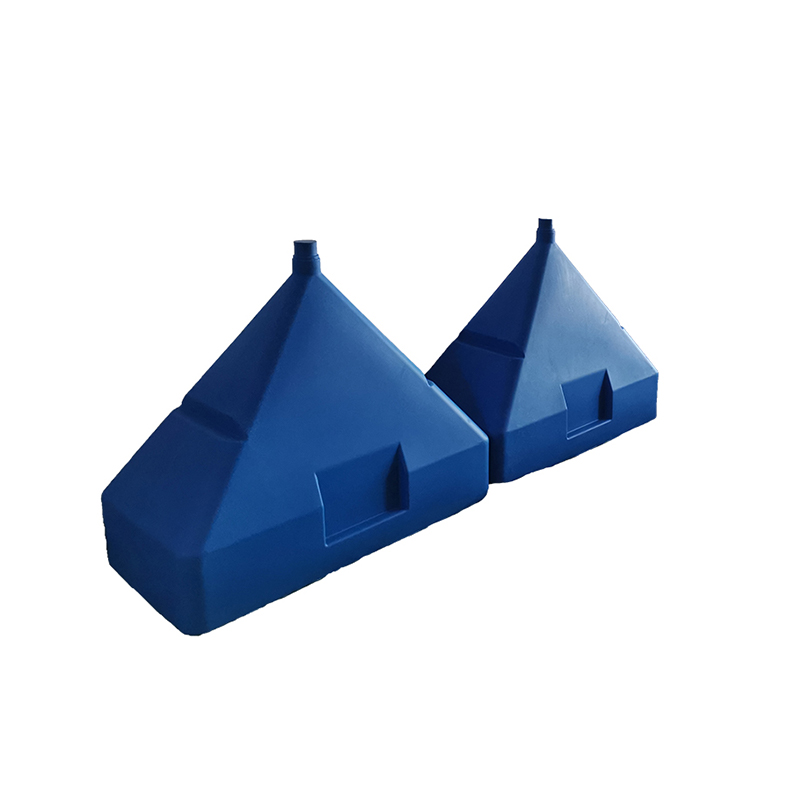

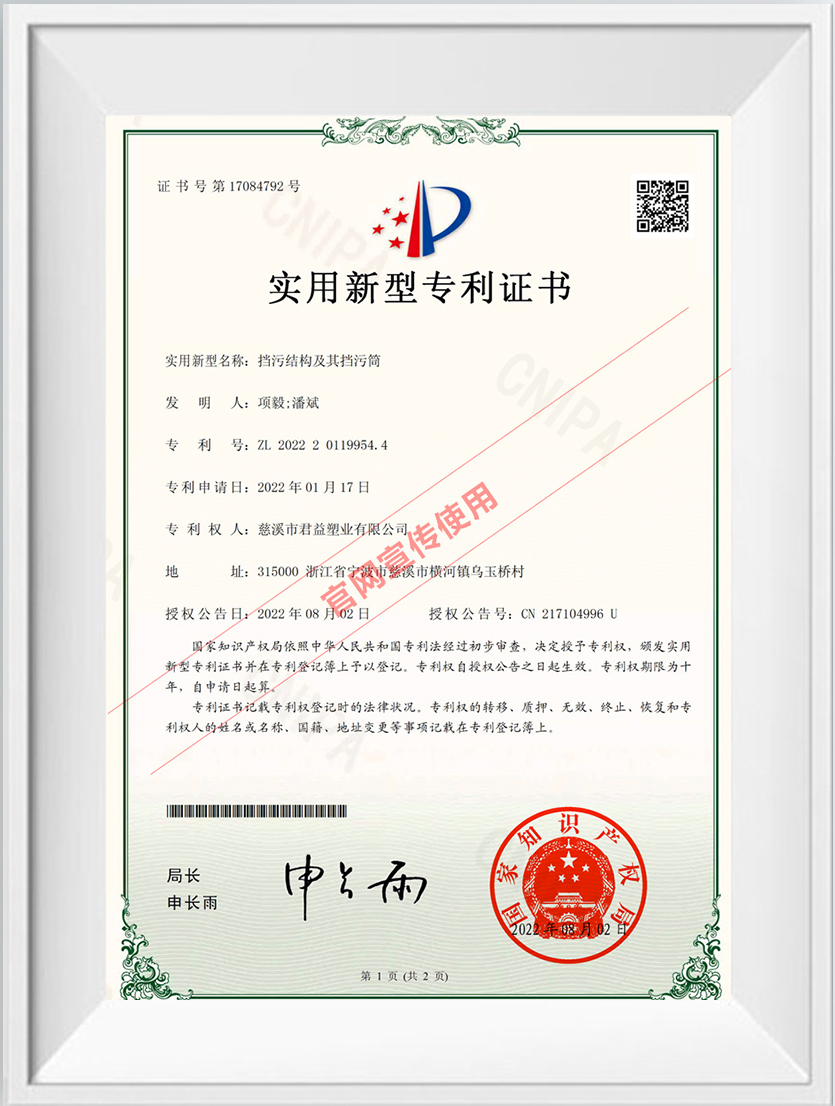

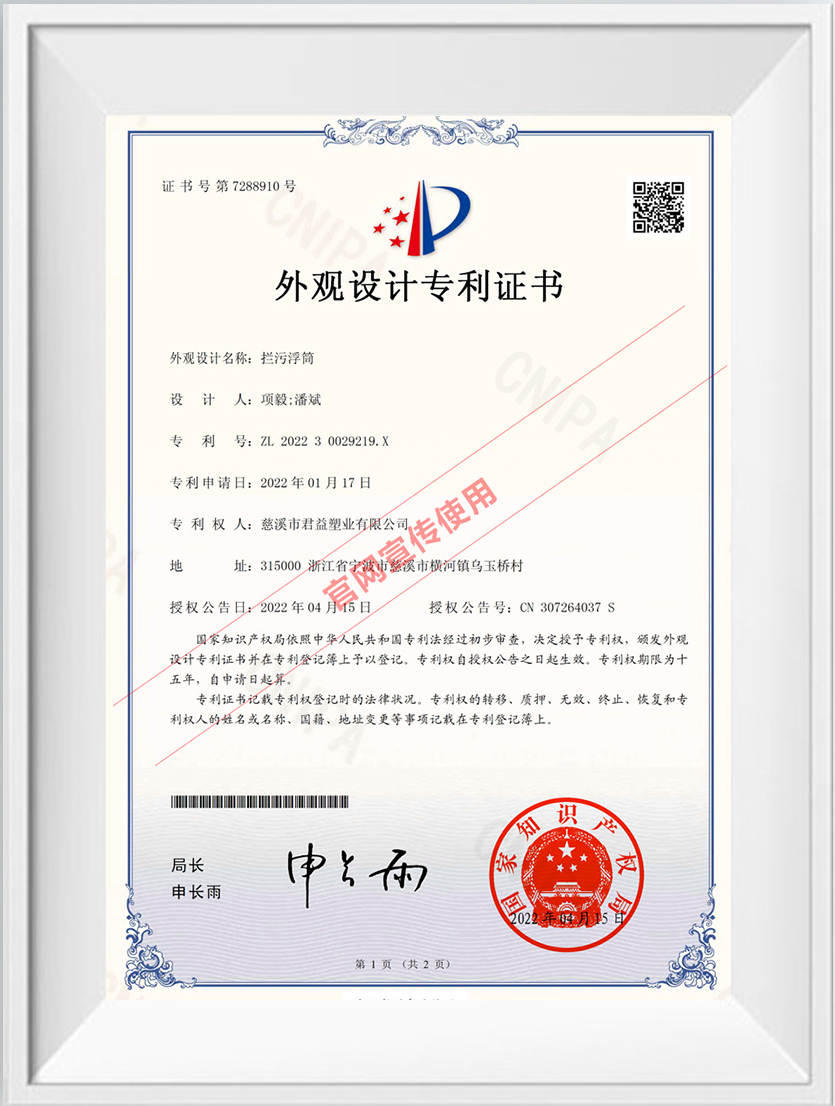

As China Rotomolding Equipment Shell Manufacturers and Rotomolding Equipment Shell Suppliers, we have won the trust and support of our customers with our stable product quality, R&D strength and after-sales service. The company's main business covers the design and research and development of floating body products. It specializes in the production of marine floats, warning floats, buoys, navigation marks, pipeline dredging floats and other types of marine equipment floating bodies. It also provides OEM and ODM services to meet the individual needs of customers.

The company has advanced production equipment, including dozens of rotating tower rotational molding machines, shuttle rotational molding machines, swing open flame rotational molding machines, and thousands of product molds to ensure the diversification of foaming types and products inside the floating body. of high quality.

Junyi Plastic's service commitment is that our professional team will provide customers with a full range of pre-sales, sales, and after-sales services to ensure that customers can receive high-quality technical support. We value the trust of our customers and always adhere to the service concept of "customer-centric, creating value for customers". In the service process, we continue to accumulate experience, improve service quality, and strengthen service intensity. Through unremitting exploration and continuous improvement, we have established a high-quality and complete after-sales service system. We always start from the actual needs of customers, not only solving customers' worries, but also committed to improving the added value of products.

-

Founded In

0+ -

Production Lines

0+ -

Employee

0+ -

Plant Area

0㎡+

-

-

Floating docks are essential structures for a variety of waterfront applications, offering support for boats, water sports, and leisure activities. Th...

READ MORE -

In the field of industrial design, an equipment shell is more than just the “face” of a product; it is the primary line of defense protecting delicate...

READ MORE -

A 10 Tons PE Mixing Barrel is a critical piece of equipment in the plastic processing industry, primarily used for the blending, homogenizing, and mel...

READ MORE

1.The Advantages of LLDPE Rotomolding Equipment Shells

LLDPE (Linear Low-Density Polyethylene) is widely recognized for its exceptional properties that make it ideal for manufacturing rotomolded equipment shells. One of the primary advantages of LLDPE in this context is its outstanding impact resistance. During the rotomolding process, LLDPE resin is evenly distributed within the mold and heated to create a seamless, uniform shell. This seamless construction helps distribute impact forces evenly throughout the shell, reducing the risk of damage to internal equipment during handling, transportation, or accidental impacts.

In industries where equipment durability is crucial, such as construction, agriculture, and automotive sectors, LLDPE rotomolded equipment shells provide reliable protection against physical impacts. This impact resistance ensures that critical devices and components remain intact and operational, minimizing downtime and maintenance costs associated with equipment damage.

LLDPE rotomolded shells exhibit robust pressure resistance characteristics. These shells are designed to withstand internal pressures without deformation, making them suitable for applications where containment of liquids, chemicals, or sensitive equipment is essential. Whether used in chemical storage tanks, water treatment systems, or industrial machinery enclosures, LLDPE shells maintain structural integrity under varying pressure conditions, ensuring safety and reliability in industrial operations.

2.Weather Resistance and Performance of PE Rotomolding Equipment Shells

PE (Polyethylene) materials, including LLDPE, offer superior weather resistance attributes that enhance the performance and longevity of rotomolded equipment shells. The inherent properties of PE allow these shells to withstand prolonged exposure to outdoor elements such as UV radiation, high temperatures, moisture, and chemicals. This weather resistance is critical for applications where equipment is deployed in harsh environments, such as outdoor installations in marine environments, agricultural settings, or construction sites.

PE rotomolded equipment shells maintain their structural integrity and aesthetic appearance over time, even in demanding outdoor conditions. The UV resistance of PE prevents degradation and discoloration caused by sunlight exposure, ensuring that the shells retain their functional and visual qualities throughout their service life. This resilience reduces the need for frequent maintenance and replacement, contributing to cost savings and operational efficiency for end-users across various industries.

3.Diverse Applications of Rotomolded Equipment Shells

Rotomolded equipment shells manufactured by our company serve a wide range of applications across diverse industries globally. These versatile shells are integral components in numerous sectors, including water treatment, environmental protection, electronics, automotive, agriculture, aviation, and marine industries. Each application benefits from the unique properties of rotomolded PE shells, which combine durability, weather resistance, and customization capabilities to meet specific operational requirements.

In water treatment facilities, PE rotomolded shells are used to house filtration systems, chemical storage tanks, and monitoring equipment. The chemical resistance of PE ensures the safe containment of corrosive substances without compromising shell integrity. Similarly, in environmental protection projects, these shells protect sensitive monitoring devices from environmental factors while maintaining operational reliability.

Across automotive and agricultural sectors, PE rotomolded shells house essential components such as vehicle parts, agricultural machinery components, and electronic devices. The impact resistance and durability of PE shells safeguard these components from physical damage and environmental wear, contributing to the longevity and performance of machinery and vehicles.

PE rotomolded equipment shells support applications in sports and fitness equipment, medical devices, food processing, greenhouse and gardening irrigation systems, aquatic breeding facilities, and textile printing industries. The versatility of rotomolded shells allows for customization in size, shape, color, and functional features, enabling manufacturers to tailor solutions that optimize performance and efficiency in various operational environments.

At Cixi Junyi Plastic Co., Ltd., we leverage advanced rotomolding technologies and extensive industry expertise to deliver high-quality PE rotomolded equipment shells that meet stringent quality standards and exceed customer expectations. With a commitment to innovation and customer satisfaction, we continue to expand our product offerings and capabilities to address evolving market demands across diverse industries worldwide.

English

English عربى

عربى